The Role of Lab Testing in Alcohol Quality Assurance

Explore how lab testing ensures alcohol quality, with insights into critical tests, data recording, and how to integrate results into your distillery workflow.

Quality assurance in alcohol production isn’t just about taste—it’s about safety, consistency, and regulatory compliance. Lab testing is the cornerstone of that process. Whether you're producing craft gin or large-scale spirits, implementing structured lab testing protocols is non-negotiable for a professional operation.

Critical Lab Tests in Alcohol Production

There are several essential tests that distilleries must routinely perform to maintain product integrity:

- ABV (Alcohol by Volume): This ensures legal compliance and label accuracy. Even minor discrepancies can lead to recalls or regulatory action.

- Clarity: Particularly important for products like vodka or clear gin, where haze can indicate filtration issues or unwanted compounds.

- Contaminant Testing: This includes checks for methanol, heavy metals, or microbial contamination—critical for both safety and shelf stability.

Testing protocols should be defined per product line, with batch-specific requirements stored in your QA system.

Recording Lab Data: Timing and Accuracy

Lab data must be recorded at precise stages of the production lifecycle. This includes:

- Post-fermentation (ABV, pH, gravity)

- Post-distillation (purity, ABV, clarity)

- Post-blending or flavoring (sugar, color, allergens)

Delays or errors in data entry lead to blind spots in traceability. Your distillery software should support real-time or mobile logging directly from the lab floor.

Linking Lab Results to Production Batches

Every lab result must be tied directly to a specific batch number. This enables full traceability and provides critical documentation in case of audit, recall, or complaint. In Liquor Logic, for example, lab entries can be linked to:

- Fermentation batch IDs

- Distillation runs

- Blending or final product lots

This linkage not only protects your brand—it simplifies reporting and ensures your QA team has immediate access to relevant data.

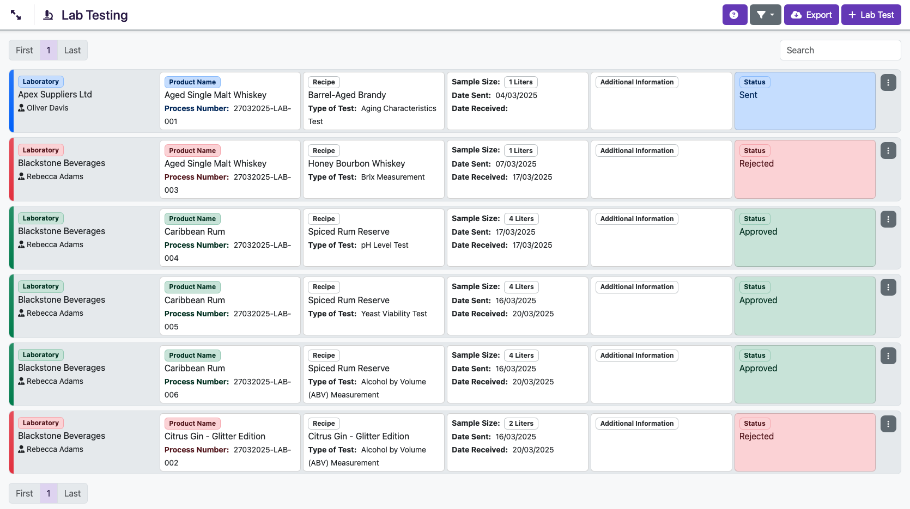

Using Lab Modules in Liquor Logic

The lab module in Liquor Logic is designed for seamless integration into the production workflow. It allows you to:

- Create test templates for different product types

- Input and store results for ABV, clarity, sugar, pH, etc.

- Flag out-of-spec results and generate alerts

- Review historical lab trends across batches

With built-in audit trails and linked production records, Liquor Logic ensures that lab testing becomes part of your operational DNA—not just an afterthought.

Conclusion

Lab testing is not just a checkbox—it’s an ongoing commitment to quality. From regulatory compliance to consumer trust, your lab results define the standard of your product. By leveraging lab modules in your distillery software, you gain control, transparency, and peace of mind that every bottle meets your exact specifications.

Back