Monitoring Recipes and Formulations in Distilleries: A Key to Consistency, Compliance, and Innovation

Discover why precise recipe monitoring is crucial in modern distilleries. Learn how structured digital systems support mash bill management, flavor development, cost control, and regulatory compliance.

Monitoring Recipes and Formulations in Distilleries

In the world of distillation, precision isn't just a luxury—it’s a necessity. Whether you're crafting bourbon, gin, or schnapps, recipe monitoring is central to maintaining quality, ensuring compliance, and fostering innovation. As distilleries move from small-batch craft production to larger-scale operations, implementing a structured and scalable recipe management system becomes critical. Let’s explore the key aspects of recipe tracking and how software can transform this foundational process.

1. Mash Bill Management

The mash bill—your grain recipe—is the foundation of spirits like bourbon and rye. Proper mash bill management starts with standardizing each formula with accurate ingredient percentages. This ensures consistency across batches and protects your brand integrity. Advanced distillery software allows you to track recipe versions, document every change, and analyze yield performance over time. More importantly, it helps ensure legal compliance with local and international spirit classifications. Whether scaling from test batches to full production or responding to regulatory audits, accurate mash bill records are essential for operational success.

2. Formulating Flavoured Blends

When developing flavored spirits such as gin or schnapps, recipe documentation goes far beyond base ingredients. You'll need detailed sheets outlining each botanical or additive, its origin, and the method of extraction—whether it's maceration, vapor infusion, or steeping. Documenting sensory evaluations and lab analyses is critical for refining flavor profiles. Each tweak should be logged to ensure reproducibility. This enables your team to revisit, scale, or legally defend formulations with confidence, preserving your competitive edge in a crowded market.

3. Linking Recipes with Stock and Cost Control

A strong recipe tracking system should integrate directly with your inventory and costing modules. This allows for automatic cost calculations per litre or bottle—factoring in ingredients, losses, labor, and overhead. With every production run, ingredient stocks should be adjusted automatically to maintain real-time accuracy. Not only does this improve day-to-day stock visibility, but it also enhances purchasing strategies and supplier negotiations by giving you insight into usage patterns and cost drivers.

4. Monitoring ABV, Sugar Content, and Allergens

Compliance isn’t optional—especially when it comes to alcohol content, sugar additions, and allergen labeling. Your system should automatically calculate ABV (Alcohol by Volume) based on fermentation and dilution inputs. This is particularly important for liqueurs, where added sugars must be carefully recorded for tax and labeling purposes. Additionally, any potential allergens such as honey, nuts, or gluten must be tracked at the recipe level to ensure transparency and consumer safety. Accurate data helps ensure your labeling meets legal requirements in every market you operate in.

5. Digital Tools That Make a Difference

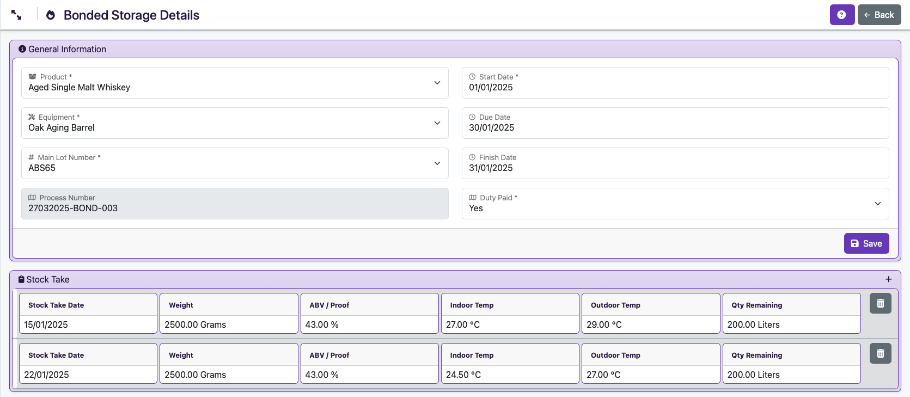

Modern distilleries are turning to digital solutions like Liquor Logic to streamline recipe tracking. These tools go beyond basic formulations—they provide version control, costing breakdowns, batch history, stock integration, and compliant reporting. Most importantly, they create production sheets that are accurate, traceable, and easy to use across your team—from the cellar to the lab.

Conclusion

In today’s competitive distilling landscape, recipe and formulation tracking is no longer optional—it’s strategic. A reliable system ensures product consistency, regulatory compliance, and cost control, all while creating space for innovation. Whether you're producing your first small batch or scaling up for mass distribution, the right digital tools will help you grow confidently while maintaining the heart of your craft.

Back