Understanding the Alcohol Production Lifecycle: From Raw Materials to Bottling

Explore the full alcohol production lifecycle—from fermentation to bottling—with insights into key data points, software tracking, and batch traceability to streamline operations and ensure compliance.

In alcohol manufacturing, every step from raw materials through to the final bottle matters. A deep grasp of the alcohol production lifecycle is essential—not just for quality control, but for operational efficiency, regulatory compliance, and traceability. Let’s break down the critical phases, the key data you need to capture, and how software tracking can transform your process.

From Raw Materials to Bottling: The Core Stages

Fermentation is where it all begins. Yeast converts sugars in your raw materials (grain, fruit, cane, etc.) into alcohol and CO2. Monitoring pH and specific gravity (SG) here is vital to ensure fermentation proceeds as expected, avoiding off-flavors or stalled batches.

Next comes distillation, the art and science of concentrating alcohol and refining the spirit profile. Keeping a close eye on ABV (alcohol by volume) throughout distillation helps maintain product consistency and meet legal requirements. It’s not just about strength—it’s about quality.

After distillation, blending allows producers to craft the final flavor profile by combining different batches or spirit types. This stage demands careful documentation to ensure reproducibility and traceability.

Finally, the product moves to bottling, where the batch is sealed and labeled. This last step completes the lifecycle but is also critical for tracking—batches must be traceable all the way from fermentation tanks to retail shelves.

Key Readings: What to Measure and Why

- pH: Influences fermentation health and flavor stability.

- Specific Gravity (SG): Tracks sugar conversion during fermentation.

- ABV: Ensures alcohol concentration meets standards and taste profiles.

Recording these measurements accurately at each stage forms the backbone of quality control.

The Power of Software Tracking

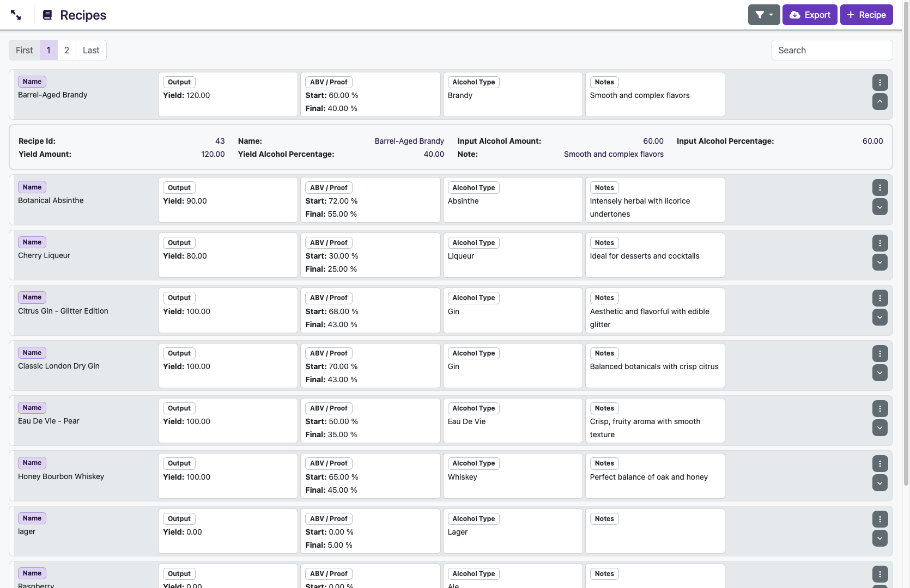

Manual tracking is outdated and risky. Modern liquor manufacturing demands software solutions that capture fermentation data logging, distillation tracking, and blending records in real time. Liquor Logic’s platform offers tailored modules to monitor every critical parameter with precision and ease. This digital approach reduces human error, speeds up decision-making, and ensures all production steps comply with excise and safety regulations.

Batch Traceability and Documentation

Traceability isn’t optional—it’s mandatory. Being able to trace a bottle back to its raw materials, fermentation batch, distillation run, and blending profile protects your brand and simplifies audits. Comprehensive documentation also supports recall procedures if needed and enhances consumer trust.

Conclusion

Understanding the alcohol production lifecycle is the foundation for any successful winery, distillery, brewery, or cidery. With precise data collection, robust software tracking, and airtight documentation, you can control quality, streamline production, and scale confidently.

Back