Streamlining Inventory Management in Alcohol Production: Enhancing Efficiency and Compliance

Discover how streamlining inventory management can revolutionize alcohol production. Learn about the benefits of using software to track raw materials, manage bulk vs. bottled stock, and ensure compliance with regulations for smoother operations.

Streamlining Inventory Management in Alcohol Production

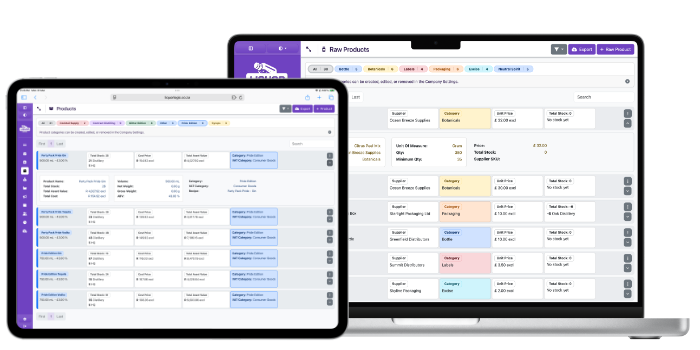

Starting an alcohol production business often begins with a passion for crafting, and many brewers, winemakers, or distillers start in their garages or basements. What begins as a hobby can quickly turn into a thriving business, and as production ramps up, managing inventory efficiently becomes crucial. Maintaining a smooth production process, ensuring product quality, and staying profitable are key to long-term success. Integrating inventory management software from the start is essential. As alcohol production companies scale to meet demand, they must automate various processes to streamline operations. Manual systems are no longer feasible for larger volumes of production. Optimizing stages like brewing, distilling, or winemaking helps reduce losses, save time, and ensure consistent product quality. Streamlining production also minimizes waste, using resources like water, energy, and raw materials (such as hops, grains, or yeast) efficiently, reducing costs and maximizing profits. Optimized logistics and stock control prevent stockouts or overstocking, balancing supply with demand. Automation of repetitive tasks, such as inventory tracking and ordering, saves time and reduces errors. Without inventory management software, it’s like trying to navigate a busy street without a map. The right software allows you to track raw materials like grains, botanicals, barrels, and bottles in real-time, ensuring that stock levels are accurate and replenished in time to avoid production delays. Automated replenishment alerts further ensure that supplies are always available when needed.

Streamlining Production: Why It Matters

When a young alcohol production company lands a major deal, it needs to scale up operations quickly. This means automating various processes to streamline production. Optimizing different stages of brewing, distilling, or winemaking helps reduce losses, save time, and produce more consistently. Saving resources, such as water, energy, and raw materials like malt or hops, is key. Streamlining production ensures these resources are used efficiently. Optimized logistics and stock management prevent shortages or overstocking, helping you balance supply with demand. Automation, even on a small scale, saves valuable time and minimizes errors. Having a clear process in place ensures smoother operations and more predictable results, leading to better profit margins in the long run.

The Benefits of Inventory Software in a Distillery

Inventory software offers a real-time tracking solution for raw materials like grains, botanicals, barrels, and bottles. This brings a massive improvement in production efficiency. With the right system in place, production delays due to shortages or overstocking are a thing of the past. Everything you need is available when you need it. Key benefits include traceability, automated replenishment alerts, and real-time tracking. Traceability ensures you can track each batch of spirits from raw product to finished product, ensuring consistency, quality, and regulatory compliance. Automated replenishment alerts ensure that stock levels fall below a certain threshold, preventing delays and ensuring timely replenishment of key ingredients. With the right system, stock is no longer a point of concern, allowing the distillery to focus on production.

Expiry, Location, and Bonded Tracking

Efficient stock management in alcohol production hinges on tracking key factors such as expiry dates, stock locations, and bonded warehouse compliance. Expiry date tracking ensures raw materials and finished products are used before their expiration, minimizing waste and ensuring product quality. Location tracking optimizes warehouse space and increases workflow efficiency. Bonded warehouse tracking ensures compliance with customs regulations, ensuring stock cannot be removed until excise duties are paid. Together, these systems streamline operations, reduce waste, and keep the business compliant with regulatory standards.

Back